Tomato sorting & packing

Turnkey solutions

Smart, precise and efficient sorting, grading and packing solutions, tailored to your process and tomatoes. Based on more than 60 years of experience, Aweta translates your specific requirements into innovative tomato sorting and packing solutions. Our turnkey solutions are easy to operate, user friendly and designed to robustly serve your business for many years.

External grading

The Ultra Vision camera setup is our most advanced camera solution. Thanks to Hyperspectral Imaging and the use of 4 cameras, the total surface area of your tomatoes is seen multiple times, making it possible to generate a 3D representation of the product. Combining this 3D representation with Deep Learning AI technology makes it possible to accurately classify each individual tomato in the correct defects category.

- Crownless

- Split

- Scarring

- Cut damage

- Sun scald

- Blossom end rot

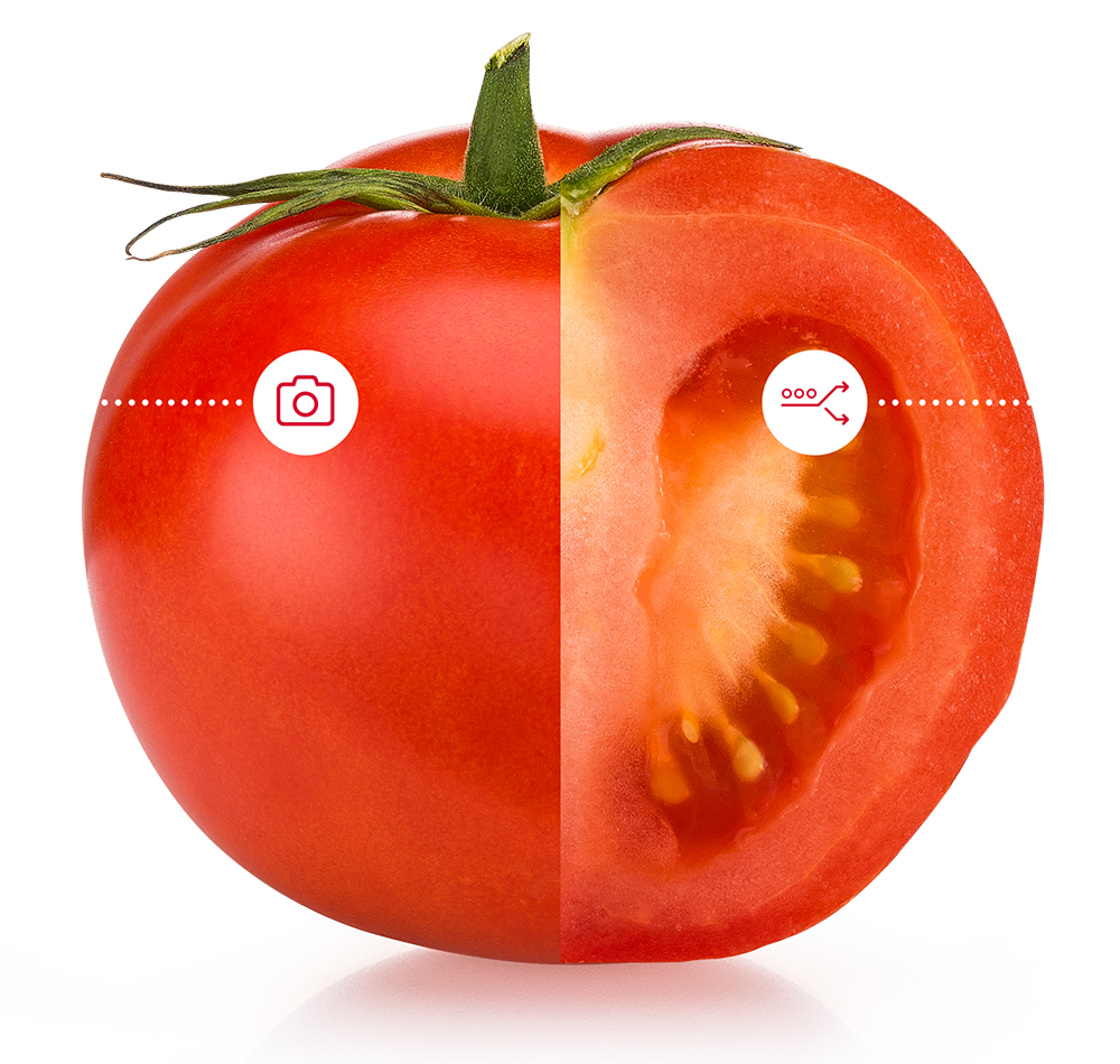

Internal grading

Adding most value

With 60+ years of experience, we combine smart technology and produce expertise to deliver tailor-made systems that fit your needs.

Understand

We listen, adapt and deliver solutions that perfectly match our csutomer's produce, market and goals. With 60+ years of expertise, we're the trusted partner of choice in the world of sorting and packing technology.

Care

With 24/7 global support, a strong local presence, and dedicated teams, we build lasting relationships and strive to make a positive global impact. We ensure reliability and peace of mind, day after day, season after season.

Excel

Every system we build reflects our craftmanship and drive for excellence, bringing together precision engineering, lasting quality and dedicated service to deliver maximum value for our global customers.

Innovate

Innovation is in our DNA. From superior vison systems to the most user-friendly software, we lead in automation, quality grading and turnkey solutions, empowering our customers to grow and succeed.

"Fast, accurate and built exactly for our needs"

Aweta’s system runs flawlessly: it’s fast, accurate and built exactly for our needs. They are committed to helping our business grow.

Frontname Lastname - CEO Company

"Fast, accurate and built exactly for our needs"

Turnkey tomato sorting, grading and packing solution

We understand your tomatoes are valuable, delicate, diverse and in high demand. That’s why we deliver smart, tailor-made sorting and packing systems that handle every tomato with care and precision.

Infeed

With tailor-made solution for your infeed systems, we will enhance your operation, increase your production and decrease your maintenance costs.

Bin dumper / Rotary box dumper

Whether you choose automatic or manual feeding, Aweta’s infeed systems deliver gentle handling and a consistent, even flow of tomatoes to your grader, ensuring efficiency and product quality.

-

Gentle product handling

-

Consistent flow to grader

-

Customizable setup

-

Reduced damage, higher output

Grading & sensors

Precision matters. Aweta’s grading systems use leading vision and sensor technology to sort every tomato by size, color, shape, and quality, inside and out.

Take control over quality and output

Our tomato sorting technology combines speed, accuracy, and gentle handling to give you total control over quality and output.

-

State-of-the-art vision and sensor systems

-

External and internal quality detection

-

High-speed, gentle singulation

-

Consistent grading for all tomato types

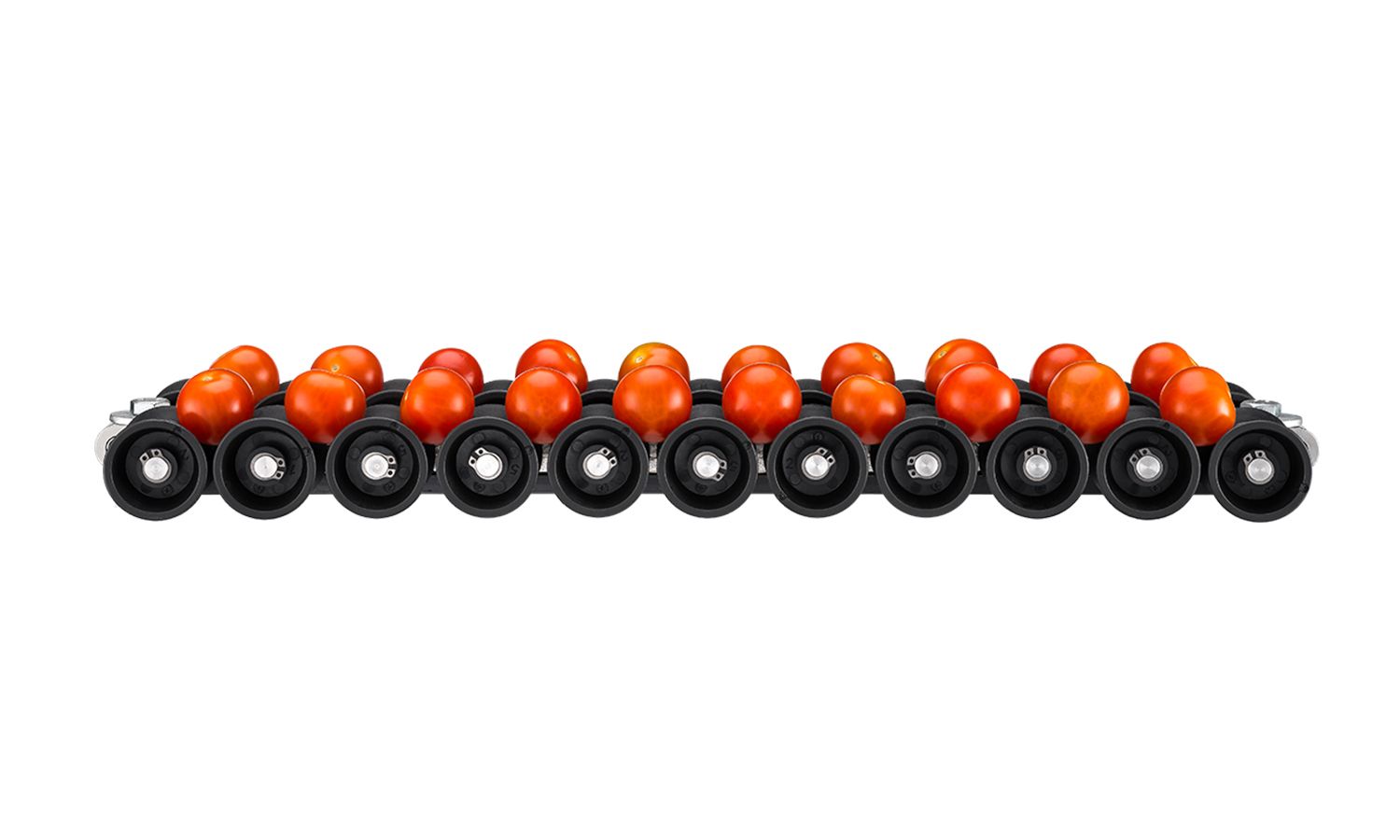

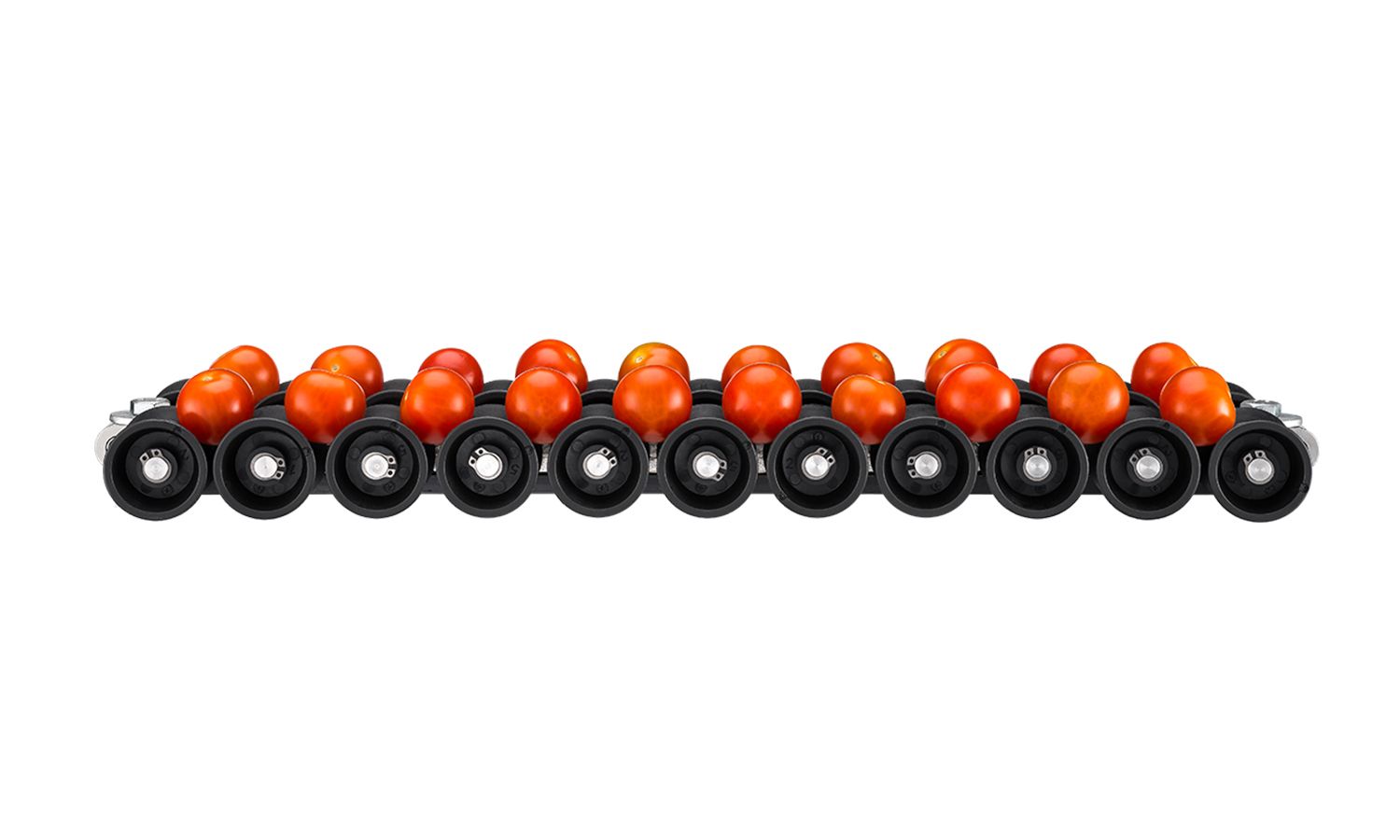

Rollerstar

Aweta's Rollerstar machines are specifically designed for a wide range of product sizes. The Rollerstar is fast, smooth and efficient.

- Perfect singulation

- Optimal camera presentation

- Accurate weight measurement

- Flexible design lay-out

Cupsizer & Pentacup

Aweta's cupsizer machine is specifically designed to handle tomatoes. Thanks to the unique diabolos and cups, our automated singulator can align and rotate the tomatoes without manual operators. A high-speed version of is available under the name Pentacup.

- Robust design, extra thick shafts

- Ensures perfect singulation

- Optimal camera presentation

- Reduces labour costs

Millistar

The Milistar is designed for small products such as cherry tomatoes. After grading, the products will be positioned into the outlets by use of air-valves.

- Robust and flexible design

- Ensures perfect singulation

- Optimal camera presentation

- High speed performance

External grading with ultra vision

The Ultra Vision camera setup is our most advanced camera solution. Thanks to Hyperspectral Imaging and the use of 4 cameras, the total surface area of your tomatoes is seen multiple times, making it possible to generate a 3D representation of the product. Combining this 3D representation with Deep Learning AI technology makes it possible to accurately classify each individual tomato in the correct defects category.

Internal grading

The Inscan Pulse internal quality sensor system makes use of spectroscopy to non-destructively assess the internal quality of your product. This allows you to evaluate the maturity of each individual tomato and optimize batch quality thus providing a perfect product to your customers.

-

Sorting

Take control over quality and output

Our tomato sorting technology combines speed, accuracy, and gentle handling to give you total control over quality and output.

-

State-of-the-art vision and sensor systems

-

External and internal quality detection

-

High-speed, gentle singulation

-

Consistent grading for all tomato types

Millistar

The Milistar is designed for small products such as cherry tomatoes. After grading, the products will be positioned into the outlets by use of air-valves.

- Robust and flexible design

- Ensures perfect singulation

- Optimal camera presentation

- High speed performance

Rollerstar

Aweta's Rollerstar machines are specifically designed for a wide range of product sizes. The Rollerstar is fast, smooth and efficient.

- Perfect singulation

- Optimal camera presentation

- Accurate weight measurement

- Flexible design lay-out

Cupsizer & Pentacup

Aweta's cupsizer machine is specifically designed to handle tomatoes. Thanks to the unique diabolos and cups, our automated singulator can align and rotate the tomatoes without manual operators. A high-speed version of is available under the name Pentacup.

- Robust design, extra thick shafts

- Ensures perfect singulation

- Optimal camera presentation

- Reduces labour costs

-

-

Vision selector

External grading with ultra vision

The Ultra Vision camera setup is our most advanced camera solution. Thanks to Hyperspectral Imaging and the use of 4 cameras, the total surface area of your tomatoes is seen multiple times, making it possible to generate a 3D representation of the product. Combining this 3D representation with Deep Learning AI technology makes it possible to accurately classify each individual tomato in the correct defects category.

-

Inscan Pulse

Internal grading

The Inscan Pulse internal quality sensor system makes use of spectroscopy to non-destructively assess the internal quality of your product. This allows you to evaluate the maturity of each individual tomato and optimize batch quality thus providing a perfect product to your customers.

Ready to boost

your tomato line?

Let’s build the right solution for your tomato line, designed for performance, precision and results.

Packing & palletizing

Aweta tailors your packaging to fit your market, crates, boxes, bags, or punnets, all handled with care. Labels with key data ensure full traceability and supply chain confidence.

Packing tables & stations

With our packing tables and stations you can achieve maximum productivity while packing your tomatoes in boxes, trays or any other packaging.

-

Designed for speed and efficiency

-

Suitable for various packaging types

-

Ergonomic setup for operator comfort

-

Seamless integration with your sorting line

Bin and box fillers

Looking for a way to increase your productivity? With our semi or fully automatic box fillers you will be able to take your production to the next level.

-

Pack into boxes, trays, or punnets

-

Semi or fully automatic options

-

Gentle product handling

-

Fast, efficient operation

Accuveyor

Aweta’s Accuveyor system ensures smooth and continuous product flow by buffering packed boxes before palletizing. This guarantees consistent line performance and optimal packing efficiency.

-

Maintains steady flow between packing and palletizing

-

Reduces downtime and bottlenecks

-

Adapts to varying speeds and box sizes

-

Ensures seamless line coordination

Palletizing

Our palletizing systems are fully automated and integrated with smart supervision and strapping technology. They deliver perfect stack formation, stability and high-speed performance for any packing line.

-

Fully automated pallet stacking

-

Integrated strapping for load stability

-

Consistent, high-speed performance

-

Designed for maximum efficiency and reliability

-

Packing logistics

Packing tables & stations

With our packing tables and stations you can achieve maximum productivity while packing your tomatoes in boxes, trays or any other packaging.

-

Designed for speed and efficiency

-

Suitable for various packaging types

-

Ergonomic setup for operator comfort

-

Seamless integration with your sorting line

-

-

Packing logistics

Bin and box fillers

Looking for a way to increase your productivity? With our semi or fully automatic box fillers you will be able to take your production to the next level.

-

Pack into boxes, trays, or punnets

-

Semi or fully automatic options

-

Gentle product handling

-

Fast, efficient operation

-

-

Packing logistics

Accuveyor

Aweta’s Accuveyor system ensures smooth and continuous product flow by buffering packed boxes before palletizing. This guarantees consistent line performance and optimal packing efficiency.

-

Maintains steady flow between packing and palletizing

-

Reduces downtime and bottlenecks

-

Adapts to varying speeds and box sizes

-

Ensures seamless line coordination

-

-

Packing logistics

Palletizing

Our palletizing systems are fully automated and integrated with smart supervision and strapping technology. They deliver perfect stack formation, stability and high-speed performance for any packing line.

-

Fully automated pallet stacking

-

Integrated strapping for load stability

-

Consistent, high-speed performance

-

Designed for maximum efficiency and reliability

-

Software

Our high-end software systems collect an enormous amount of data about your tomatoes. This allows you to define quality based on defects and categorize based on overall quality characteristics of the batch, ensuring you have full control over your sorting and packing process. Aweta is industry leading in the field of tracking & tracing and plant control. This means you reach the highest level of flexibility while maintaining maximum control over your information.

User interface

Flow Master is a user-friendly interface that allows you to control your sorting and packing-needs in a very simple and efficient way. It is a full operating system and can be used for all involved parties: from sorting to packing and palletizing your tomatoes.

-

Centralized control of the entire line

-

Real-time monitoring and adjustments

-

Empowering operators to make informed decisions

-

Consistent, high-performance processing

Plant control

Our Flowmaster system is controlled from a central control panel assuring you of rapid and accurate processing with optimum reliability year in year out.

-

Complete integrated plant solution

-

One screen with a clear structure

-

Easy to integrate in ERP systems

-

Article based

-

Tablet and phone compatible

Track & trace

-

Full product traceability from start to finish

-

Real-time data collection and tracking

-

Easy export to third-party databases

-

Supports quality control and compliance requirements

-

Flowmaster

User interface

Flow Master is a user-friendly interface that allows you to control your sorting and packing-needs in a very simple and efficient way. It is a full operating system and can be used for all involved parties: from sorting to packing and palletizing your tomatoes.

-

Centralized control of the entire line

-

Real-time monitoring and adjustments

-

Empowering operators to make informed decisions

-

Consistent, high-performance processing

-

-

Rapid processing

Plant control

Our Flowmaster system is controlled from a central control panel assuring you of rapid and accurate processing with optimum reliability year in year out.

-

Complete integrated plant solution

-

One screen with a clear structure

-

Easy to integrate in ERP systems

-

Article based

-

Tablet and phone compatible

-

-

Full traceability

Track & trace

Our Track & Trace systems provide extensive feedback to 3rd party tools. The system records the entire route of your product data during the sorting and packing process. Information is collected and can be exported to 3rd party databases for further analysis.-

Full product traceability from start to finish

-

Real-time data collection and tracking

-

Easy export to third-party databases

-

Supports quality control and compliance requirements

-

Projects around the globe

See how we help fresh produce companies thrive with smart sorting and packing solutions.

FAQ's about our technology

Aweta uses advanced 3D vision and sensor systems to grade both the external and internal quality of fruits and vegetables. Technologies like Advanced Vision and Inscan detect size, shape, color, ripeness, sweetness, firmness and defects, ensuring precise and consistent sorting.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Who we work for

Contact us

Want to learn more, request a quote or get support? Just fill out the contact form, we’re here to help!